-

What if you could prevent major incidents, while building operational excellence?

-

We help you develop world class leadership and a culture of excellence.

-

Improving culture, productivity and safety for leaders and their teams.

-

Helping leaders reduce major incidents and improve operational performance using proven lessons from the U.S. Nuclear Navy.

- What if you could prevent major incidents, while building operational excellence?

- We help you develop world class leadership and a culture of excellence.

- Improving culture, productivity and safety for leaders and their teams.

- Helping leaders reduce major incidents and improve operational performance using proven lessons from the U.S. Nuclear Navy.

-

What if you could prevent major incidents, while building operational excellence?

-

We help you develop world class leadership and a culture of excellence.

-

Improving culture, productivity and safety for leaders and their teams.

-

Helping leaders reduce major incidents and improve operational performance using proven lessons from the US Nuclear Navy.

- What if you could prevent major incidents, while building operational excellence?

- We help you develop world class leadership and a culture of excellence.

- Improving culture, productivity and safety for leaders and their teams.

- Helping leaders reduce major incidents and improve operational performance using proven lessons from the US Nuclear Navy.

Drawing from High Reliability Organization (HRO) principles ingrained since the inception of Rickover’s Nuclear Navy, High Reliability Group empowers your organization to achieve unmatched safety, efficiency, and leadership – driving your operations to reach the highest industry standards.

Our Solutions

High Reliability & Operational Excellence Services

Culture Transformation Services

Transforming Operations Through Systematic Cultural Evolution

Our HRO Culture Transformation projects recognize that sustainable change happens through carefully sequenced interventions: preliminary assessments that establish your baseline and quick wins, immediate actions that address critical gaps and build credibility, and ongoing initiatives that embed new behaviors and sustain long-term excellence. HRG’s model for building a high reliability organization factors in management systems, culture, leadership and feedback, all working in alignment.

Whether you’re beginning your transformation journey or accelerating existing efforts, our systematic approach ensures each phase builds upon the last, creating lasting organizational change that drives operational excellence and prevents major incidents.

Rapid Operational Assessment (72h)

High risk, high consequence operations can drift from best practice long before an incident exposes the cracks. Our Rapid Operational Assessment (ROA) gives senior leaders an unfiltered, observation‑driven picture of their organization’s reliability posture – fast.

In just three days, our former U.S. Nuclear Navy commanders and industry experts uncover hidden vulnerabilities and areas of excellence you can immediately replicate across the enterprise.

Leadership Coaching & Training (Human Factors)

Practical skills that reduce error and speed recovery: pre-task briefs, error-trap spotting, speak-up behaviors, just-culture responses, and high velocity after action reviews. We coach in the work using micro- drills and real scenarios.

Deliverables: role-based playbooks, job aids, observation cards, coaching plans, and AAR scripts.

Outcome: fewer human-error events and faster detection/correction.

OEMS Design & Support

We design and embed your Operational Excellence Management System so execution is consistent across shifts and sites: tiered daily management, leader standard work, PDCA problem solving flow, escalation paths, and ensuring your operations playbooks are fit for purpose.

Deliverables: OEMS blueprint, RACI, KPI definitions, board/templates, audit checklists, and enablement guides.

Outcome: stable throughput, tighter variability, and predictable performance.

Leadership Development Program (LDP)

Build leaders who marry technical precision with human reliability. Cohorts use HRG’s CARE framework (Communication, Accountability, Responsibility, Engagement) and a blended cadence—brief on-site intensives plus live virtual modules and field assignments—tied to clear performance metrics.

Choose a 30-day Flex Pass, a single skill module, or a 12-month mastery path that flexes around shifts and outages, culminating in a capstone that proves ROI.

Maritime Quality Assurance Services

Workshops Services

HRO Leadership Workshops

Hands-on sessions for executives and their teams to run a high-reliability operation in the real world. We practice tiered daily management, leader standard work, incident learning, and human factors (pre-task briefs, cross-checks, just-culture responses). Live drills in situ translate principles into repeatable behaviors. Deliverables: role-based behavior cards, tier meeting agendas, visual boards/templates, AAR scripts, and a 30/60/90 integration plan. Outcome: safer execution, tighter control, faster problem solving.

Decision-Making & Human Factors Workshops

Intense, scenario-driven practice for high-stakes calls under time pressure. We apply proven frameworks (pre-mortem, red teaming, OODA), error-trap spotting, and crisis communications to reduce cognitive overload and improve team coordination. Deliverables: decision playbook, Go/No-Go matrices, comms checklists, and after-action templates. Outcome: better decisions on the first try, fewer human-error events, quicker recovery.

Customized Workshops

Built from your operating context and constraints. We tailor modules—turnarounds, outage readiness, shift handover, MOC, supplier performance, audit cadence—and deliver onsite or virtual in half-day to multi-day formats. Deliverables: custom curriculum, case packets from your data, KPI definitions/dashboards, and a sequenced change plan with owners. Outcome: targeted behavior change with measurable impact on safety, quality, delivery, and cost.

Keynotes & Event Speaking

High-energy, no-fluff talks for leaders running high-risk, high-consequence operations. Our speakers translate nuclear-submarine rigor and large-scale turnarounds into simple tools your teams can use the next day—decision frameworks, human-factors habits, and management rhythms that raise reliability.

Popular Topics (Pick & Mix)

Accountability & Reliability as the Norm – just culture, role clarity, and consequence management that stick

Leadership Under Pressure: Decisions & Risk – OODA, pre-mortem, and red teaming for time-compressed calls

Human Factors & Incident Prevention (HRO) – error traps, cross-checks, speak-up behaviors, and rapid recovery

Sustainable Change & Operational Excellence – OEMS, tiered daily management, leader standard work, and KPI trees

Creating a Learning Culture – incident learning systems, AAR cadence, and psychologically safe debriefs

Attention to Detail: Quality at the Point of Work – procedural compliance, three-way communication, peer checks, and verification

Crisis Response Leadership – stabilize, communicate, and prioritize through decision cells, comms cadence, and tempo control

Safety Leadership – leading indicators, field presence, hazard recognition, and just-culture responses

Assurance Programs for Supply Chains – traceability, supplier oversight, and Level I/critical material controls

Leading Today’s Workforce – mentoring, coaching reps, and ownership behaviors for modern crews

Sustainable Change & Operational Excellence – OEMS, tiered daily management, leader standard work, and KPI trees

Operational Excellence

Accountability & Reliability as the Norm – just culture, role clarity, and consequence management that stick

Accountability & Reliability

Stabilize, communicate, and prioritize through decision cells, comms cadence, and tempo control

Crisis Response Leadership

Incident learning systems, AAR cadence, and psychologically safe debriefs

Creating a Learning Culture

Quality at the Point of Work – procedural compliance, three-way communication, peer checks, and verification

Attention to Detail

Formats

30-60 min keynotes or longer duration workshops tailored to your initiatives.

Deliverables

customized talk (pre-event discovery), audience handouts as needed

Outcome

a shared language for reliability, three behaviors to start tomorrow, and clear metrics owners can track.

Industries

HRG partners with leaders in high-risk industries, including energy, refining, chemical processing, maritime, shipbuilding, manufacturing, utilities, and critical infrastructure – to integrate safety, reliability, and performance into daily operations. By applying proven High Reliability Organization principles, we help executive teams build cultures of accountability, resilience, and disciplined leadership that prevent incidents, strengthen efficiency, and deliver sustainable results under pressure.

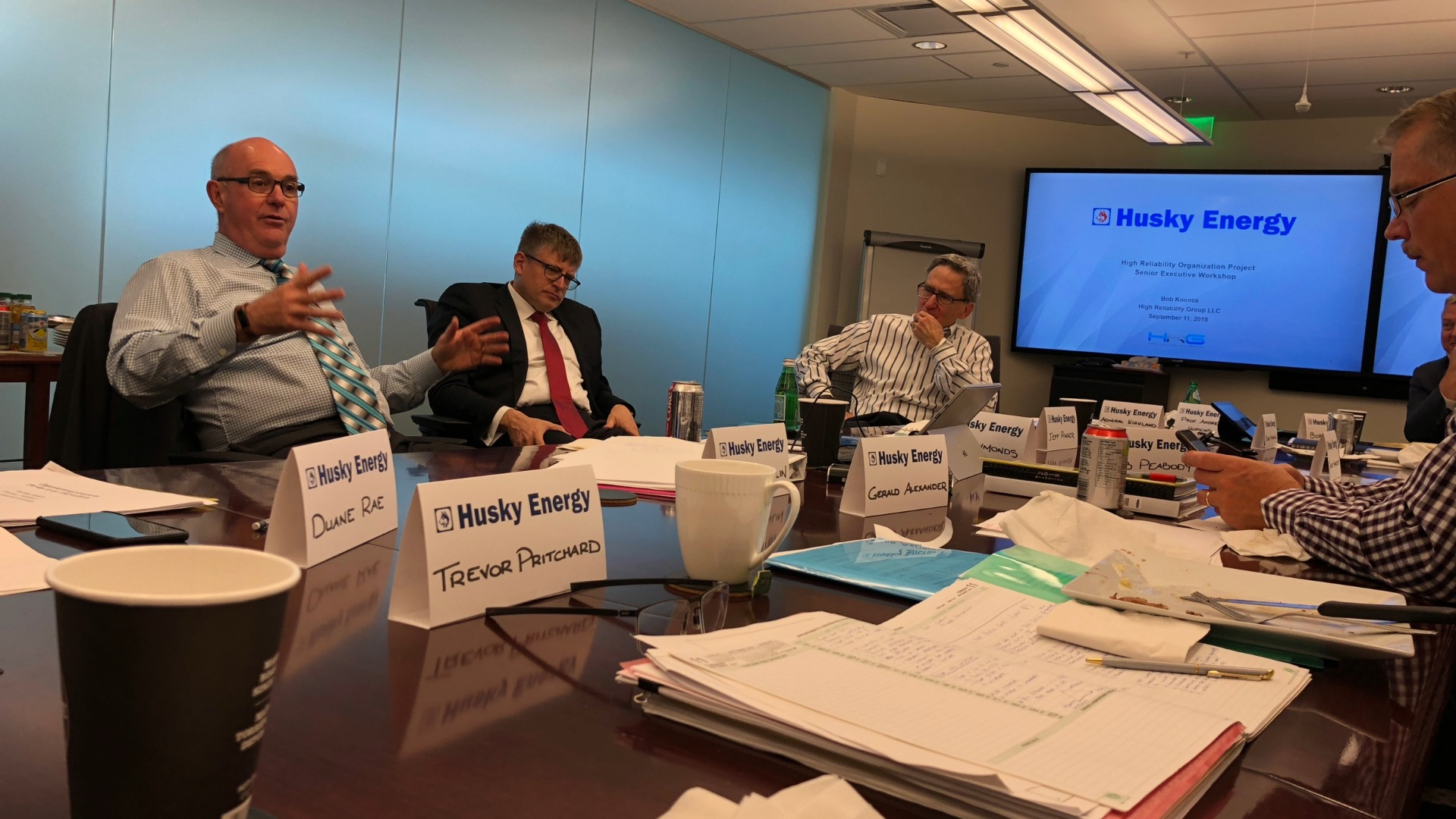

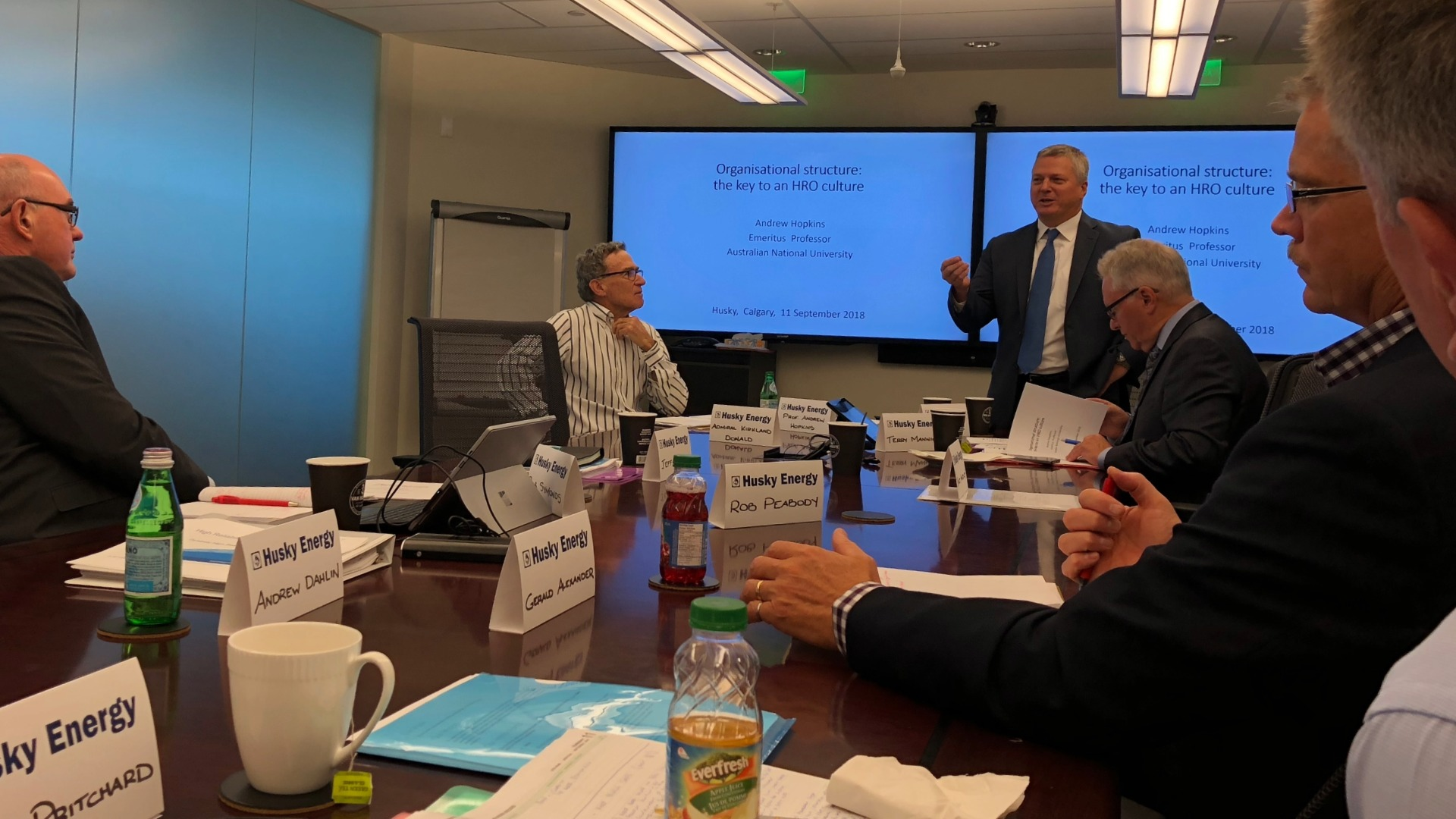

Current or Past Clients

Testimonials

Why People Love Working With Us

Results

What leaders get

30%

2-4x

72h

*Illustrative; validated with client benchmarks during discovery.

Proven Case Studies

Where we've moved the needle

Culture Transformation - Integrated O&G

Core Challenge

Refinery fire exposed cultural and process safety gaps across the enterprise.

HRG Intervention

- Enterprise-wide culture & leadership evaluation

- Embed HRO principles (questioning attitude, leadership discipline, process safety focus)

Tangible Results

- Lower incident rates; stronger metrics

- Leadership mindset shift toward reliability

Rapid Culture Change - Canadian Refinery (130 kbd)

Core Challenge

New GM needed rapid culture change before a major turnaround.

HRG Intervention

- Cultural & leadership assessment

- Design & rollout of an Operational Excellence Management System

- Hands-on turnaround planning support

Tangible Results

- HRO behaviors embedded

- Improved turnaround safety & efficiency

Field Logistics Efficiency - West Texas Upstream

Core Challenge

Inefficient scheduling caused ~$10M/yr productivity loss.

HRG Intervention

- Targeted HRO coaching

- Revamped logistics processes

Tangible Results

- 50% scheduling cycle-time improvement in 3 months

- Major cost savings

Production Uplift - Canadian Upstream Business Unit

Core Challenge

Production shortfalls driven by weak leadership coaching in HRO methods.

HRG Intervention

- Customized HRO evaluations and leader development.

Tangible Results

- Thirty percent production uplift.

- Twenty five percent cut in maintenance and commissioning costs.

Offshore Fleet Benchmark - International Deep Water Platforms, Gulf of America

Core Challenge

Underperformance across multiple offshore assets.

HRG Intervention

- HRO based operational excellence training and coaching.

Tangible Results

- Twenty percent productivity gain, new benchmark for the fleet.

Insights

Practical notes from nuclear-grade operations

Leadership

How to Build Trust Without Lowering the Bar

Creating Psychological Safety in High-Reliability Organizations

Operations

How to Build a Learning Organization

Talent

How to Build the Right Leadership from the Start

About

High Reliability Group (HRG) is a boutique consultancy that helps executive teams in high risk, high consequence industries prevent major incidents while building disciplined, high-performance operations. Founded by former U.S. Nuclear Navy leaders and industry operators, we translate the rigor, culture, and human factors discipline of Rickover’s Nuclear Navy into practical systems your teams can run every day, without adding bureaucracy or slowing the work.

We partner with senior leaders across energy, chemicals, manufacturing, maritime, utilities, and critical infrastructure. Typical engagements combine a Rapid Operational Assessment for immediate clarity, leadership coaching grounded in human factors methods, and the design/embedding of an Operational Excellence Management System (tiered daily management, leader standard work, visual control, PDCA). The result: fewer human error events, tighter variability, faster learning loops, and stable throughput where it matters most – at the point of work.

Our approach is deliberately hands-on and sequenced. We start with you on the job to establish a baseline and quick wins, then move to targeted interventions that close critical gaps, and finally institutionalize new habits through role-based playbooks, observation and coaching, and a transparent 30/60/90 plan with clear owners. We focus leaders on repeatable behaviors: pre-task briefs, cross checks, speak-up norms, just culture responses, so safety and performance are inseparable in daily decisions.

HRG is led by Founder & President Bob Koonce, a former U.S. Submarine Force commanding officer and co-author of Extreme Operational Excellence: Applying the U.S. Nuclear Submarine Culture to Your Organization. Bob and the team of senior submarine veterans, human-factors experts, and experienced industry executives, bring decades of leadership under pressure and a track record of turning reliability principles into measurable business results.

If you’re seeking fewer surprises, stronger leadership, and performance that holds under pressure, HRG is your partner. Let’s align on your objectives and build a clear, tailored path to high reliability, one your teams can execute starting now.

Leadership

Operational Excellence

Human Performance

Bob Koonce, Founder & President

Bob Koonce is the Founder & President of High Reliability Group and a former Commanding Officer in the U.S. Submarine Force (USS KEY WEST, SSN 722). With 20+ years in nuclear-powered operations, he led teams where precision, human factors, and accountability were non-negotiable. In 2016, he founded HRG to help civilian organizations apply those same high reliability standards to prevent major incidents and elevate performance.

He is co-author of Extreme Operational Excellence: Applying the U.S. Nuclear Submarine Culture to Your Organization, a practical playbook for leaders who want uncompromising standards without bureaucracy. The book distills Rickover-era principles: clear ownership, procedural discipline, relentless self-assessment, and psychologically safe learning, into tools leaders can use the next day.

Bob’s work is amplified by a senior team of submarine veterans, human-performance experts, and industry operators who turn principles into repeatable behaviors at the point of work. Together they coach leaders on the floor and embed processes so safety and performance become inseparable in daily decisions.

Extreme Operational Excellence

A practical guide to building high reliability from the U.S. Nuclear Submarine Force, co-authored by Bob Koonce.

“Extreme Operational Excellence: Applying the US Nuclear Submarine Culture to Your Organization, is one of the best books I have ever read. If you want to understand me and the way I work, read this book. If you want to understand how to really accomplish organizational excellence, read this book. If you want to understand why US Submariners are the way they are, read this book. Just read this book!”

What you’ll learn

Build a culture of uncompromising standards

Instill behaviors that prevent failure, anticipate risk, and drive sustainable improvement.

Lead with integrity and accountability

Practice relentless self-assessment

Enable teams to perform under pressure

Equip people with the mindset and tools to deliver without compromising safety or performance.

Team

our people

Meet Our Experienced Professionals

Bob Koonce

Bob served for over 20 years in the U.S. Submarine Force and retired from active duty as a Commander in 2011 after commanding USS KEY WEST (SSN 722), a nuclear submarine based in Pearl Harbor, Hawaii. During Bob’s career in the Navy he served on five different fast attack submarines and deployed overseas conducting missions critical to national security. Since leaving active duty, Bob has been a consultant to large and small businesses primarily in the Energy Industry.

Kevin Mooney

Kevin has over 36 years of leadership and management experience in both private industry and the U.S. Navy. Over the past 16 years, he has held senior leadership positions in two large North American shipyards. Kevin had previously served for 20 years as a nuclear submarine officer in the US Navy. Kevin has guided numerous organizations through challenging circumstances including transformations, turnarounds and integration following acquisition.

Jeff Hedges

Jeff has over 40 years of experience in senior leadership roles in both the military and in industry. Jeff has worked in a variety of industries in operations and HES roles including at Chevron Corporation, a privately held environmental services company, in the pulp and paper industry, and in the DOE nuclear complex.

Bryan Lethcoe

Bryan has over 30 years of experience in the US Nuclear Submarine Force and in the Oil and Gas industry, supporting onshore and offshore pipeline integrity technology development, pipeline integrity consulting, offshore drilling technical audit and field support, and LNG technical audit and operational excellence. Bryan served in the US Navy for 20 years, both in the US Submarine Force and in various leadership and staff roles in the Navy Reserve, retiring with the rank of Commander.

Juan Contreras

Juan served 20 years in the Naval Nuclear Power Program retiring in 2005. His sea service included tours on a guided missile cruiser and multiple aircraft carriers while serving as Reactor Controls Leading Chief Petty Officer. His shore duties included an instructor tour where he served as the Production Training Group Lead at the S8G training facility.

Scott Kimmel

Scott served 21 years in the Navy Nuclear Power program as both enlisted and a Commissioned Officer. During his enlisted 11 years he trained sailors for the Nuclear Power pipeline. He also had operational time on submarines. After becoming a Limited Duty Officer, he stayed with the maintenance of Naval Submarines in both shipyards and submarine tenders. During his time in the Navy, he was able to earn a Bachelor of Science degree in Human Resource Management as well as a Master’s degree in Business Administration. He retired from the Navy in 2004.

Bruce Talbot

Bruce served 31 years in the U.S. Navy Submarine Force retiring from active duty in 2012. During his career he was Reactor Controls Leading Chief Petty Officer and Engineering Department Master Chief on five fast attack submarines. He has also served in the nuclear repair department of a submarine tender, the staff of a Submarine Squadron and as a shipyard availability coordinator. His final position in the Navy was Command Master Chief of a Naval Reactors Training Facility.

Brian O'Neill

Brian served 22 years in Navy Nuclear Power and retired from active duty in 2009. He is a graduate of North Carolina State University with a Bachelor of Science in Mechanical Engineering and earned his Master in Engineering Management from Old Dominion University. He served aboard a ballistic missile/special operations nuclear submarine and multiple nuclear and non-nuclear surface warfare ships. His shore assignments include an evaluator tour at a Nuclear Power Training Unit and as Force Personnel Officer at Commander Naval Surface Forces Atlantic.

Duncan Preston

Duncan has over 40 years of experience with the U.S. Navy’s Nuclear Propulsion Program. He served 13 years enlisted and 15 years as a commissioned officer, retiring in 2008. He served on seven ships including a guided missile cruiser, two aircraft carriers, and four nuclear repair ships, including two submarine tenders forward deployed in Italy.

Duncan returned to federal service in 2011 where he held senior leadership positions at two of the Navy’s four public shipyards. As Detachment Director, he led two remote site detachments in San Diego, CA and Yokosuka, Japan supporting all Pacific Fleet aircraft carriers. In 2023 he accepted a special assignment at Naval Sea Systems Command headquarters in a high-profile position focused on improving Naval Shipyard performance.

In addition to the Navy’s Nuclear Power Training program, Radiological Controls Officer, and Quality Assurance Officer schools, he earned a Bachelor of Science in Liberal Arts from Excelsior College, a Master of Science in Global Leadership and Graduate Certificate of Project Management from University of San Diego, and a Master of Business Administration from University of Redlands.

Tim Doelger

Tim is a nuclear submarine veteran, a tech-savvy innovator, and a strategic business development expert with over 20 years of experience. He served in the U.S. Navy as a Nuclear Submarine Electronics Technician on two Nuclear Ballistic Submarines. Holding a BS in e-Business, Tim has developed extensive expertise in mar-tech, data communication, and cybersecurity solutions, collaborating with C-suite executives of Fortune 500 companies.

Paul Zorgdrager

Paul brings over 30 years of executive operational and leadership experience in Western Canadian oil and gas operations. This broad upstream oil and gas experience ranges from drilling, completions, pipeline integrity, well operations, as well as complex plant operations. He has a deep and practical understanding of High Reliability Organization principles and the work it takes to build a culture of excellence based on the HRO principles.

Paul has a Bachelor of Applied Science in Chemical Engineering from the University of Waterloo, and recently gained a Graduate Certificate in Executive Coaching from Royal Roads University in Victoria, British Columbia. Paul is based Saskatoon, Saskatchewan.

Dave Rossberg

Senior Consultant

Dave is a former U.S. Navy Submarine Warfare Officer with 15+ years in leadership, operations, and business strategy. He pairs hands-on technical credibility with executive-level consulting to strengthen leadership, culture, and operational discipline.

During seven years on active duty, Dave qualified as Officer of the Deck and Engineer on a fast-attack submarine and led multiple nuclear reactor operations divisions through two overseas deployments, complex maintenance periods, and operational nuclear inspections. As a Shift Engineer at the Navy Nuclear Power Training Unit (Charleston, SC), he oversaw training and certification for hundreds of officers and enlisted sailors entering the submarine and aircraft carrier fleets.

After active duty, Dave earned an MBA from Columbia Business School and joined L.E.K. Consulting, leading strategic growth and due diligence work for global industrial and energy clients. He later founded and ran a construction firm delivering renovation and upgrade projects for federal facilities nationwide, and subsequently launched a business strategy and leadership coaching firm focused on helping technical small-business owners build scalable, self-sustaining companies grounded in high-reliability principles.

At HRG, Dave helps executive teams drive sustainable performance improvement, elevate leadership capability, and build organizations that embody the High Reliability mindset.

Dave holds a B.S. in Materials Science and Engineering (minor in Engineering Entrepreneurship) from Penn State and an MBA from Columbia Business School. Based in New York City, he volunteers with Bunker Labs and the Institute for Veterans and Military Families and serves with Hudson River Community Sailing, mentoring local high school students.

FAQ

Answers for busy operators

What is a HRO (high reliability organization)?

A High Reliability Organization is one that operates in environments where failures or errors can have severe consequences, yet retains very low rates of adverse events. It does so through deliberate leadership, a culture of safety and reliability (not just compliance), structured and formal processes, ongoing learning, vigilance for weak signals (near misses, anomalies), high procedural discipline, mutual support among team members, and resilience to detect, respond to, and recover from unexpected situations.

What is a ROA (Rapid Operational Assessment)?

A 72-hour on-site assessment that benchmarks your operation against high-reliability standards and provides prioritized actions.

Which industries do you serve?

Energy, manufacturing, chemical/process, maritime/offshore, aviation, healthcare, defense, transportation and more.

How fast can we start?

Start with a discovery call +1 (331) 223-9722 or email [email protected]

How can the Nuclear Navy's principles be applied to my industry?

| Area | Question to Ask |

|---|---|

| Procedures & Standards | Do we have well-documented, clear procedures for critical operations? Are there checkpoints / verification steps? Is there consistency in how people follow them? |

| Leadership and Accountability | Are leaders visibly accountable for safety, reliability, quality (not just metrics)? Do they invest time in understanding front-line challenges? Do they enforce standards even under pressure? |

| Technical Competence & Training | Do people have both the knowledge and understanding of why things are done a certain way? Is there ongoing training, retraining, simulations for abnormal situations? |

| Reporting / Questioning Culture | Can people speak up when they see potential hazards or anomalies without fear of reprisal? Are near misses or small deviations reported and acted upon? |

| Empowerment / Stop-Work | Is there a mechanism for any employee to pause work if they believe something is wrong? Do we encourage that? How do we respond when someone stops work — support or pushback? |

| Redundancy & Cross-Checking | Have we built in overlapping safeguards, redundant procedures, peer-checks or audits to catch potential errors before they escalate? |

| Resilience & Learning | When things go wrong (or nearly wrong), do we systematically debrief, learn, adapt? Do we simulate/prepare for the unexpected (contingency planning)? |

| Operational Awareness | Do leaders regularly go to where the work is done, observe operations, talk with front-line staff to understand real risks? Are there feedback loops from operations to decision makers? |

How do HROs maintain performance under complex and high risk conditions?

HROs maintain performance through continuous vigilance, decentralized decision-making during crises, learning cycles, and designing for adaptability with redundancy and resilience.

What industries benefit the most from adopting HRO principles?

Industries such as nuclear energy, oil and gas, aviation, healthcare, emergency response, utilities, and critical infrastructure benefit significantly from HRO principles due to their high-risk nature.

How is mindfulness practiced operationally within HRO frameworks?

Mindfulness is practiced through near miss reporting, anomaly detection, cross checking assumptions, daily huddles, and empowering staff to speak up, maintaining acute awareness of system conditions.

What role does leadership play in sustaining a high reliability culture?

Leadership sustains HRO culture by modeling behaviors, engaging with frontline operations, allocating resources, fostering psychological safety, and supporting learning and accountability.

How do HROs detect and respond to weak signals of failure?

HROs detect weak signals through robust reporting systems, analyzing small anomalies, trend analysis, and quickly escalating and investigating potential issues.

What distinguishes HROs from other safety focused organizations?

HROs emphasize continuous vigilance, decentralized expertise, reluctance to simplify, resilience, and a culture of inquiry, going beyond compliance and checklist focused safety programs.

How can my organization become high reliability organizations in practice?

Organizations can transition to becoming a HRO through leadership alignment, safety culture initiatives, structured reporting, team training, and continuous monitoring and feedback systems.

What are the common barriers to implementing HRO principles in legacy systems?

Common barriers include rigid hierarchies, siloed structures, lack of resources, punitive cultures, over reliance on compliance, outdated infrastructure, and resistance to change.

What metrics are used to assess the maturity of a high reliability organization?

Metrics include event and near-miss rates, reporting frequency, safety culture surveys, response times, reliability of key processes, and HRO maturity model scores.

How do HROs handle change management without compromising reliability?

HROs manage change through small scale pilots, iterative learning, stakeholder engagement, maintaining redundancies, and transparent risk communication.

What is the relationship between Just Culture and high reliability?

Just Culture supports HROs by fostering a balance of learning and accountability, encouraging reporting without fear, and promoting open dialogue about errors.

How do high reliability principles intersect with DevOps or SRE in tech environments?

HRO principles align with DevOps and SRE through preemptive failure analysis, real time monitoring, resilient design, and empowering technical experts during incidents.

What training supports the transition to an HRO model?

Training includes safety culture, human factors, root cause analysis, team communication, and simulation-based learning.

Can a startup organization adopt HRO principles from day one?

Yes, by embedding psychological safety, anomaly reporting, decision decentralization, complexity awareness, and resilience into their foundational culture.

What real-world failures could have been prevented with HRO practices?

Incidents like the Three Mile Island accident, space shuttle disasters, Bhopal gas leak, and healthcare system failures highlight how early anomaly detection and resilience could have mitigated outcomes.

How do HROs integrate continuous learning into daily operations?

They use debriefs, feedback loops, open reporting, simulations, cross-training, and knowledge sharing forums to embed learning into everyday practices.

What frameworks exist for auditing high reliability in organizations?

Several frameworks exist for auditing high reliability organizations, drawing from industries such as energy, manufacturing, aviation, and software engineering. One widely referenced model is Google’s Reliability Maturity Model, which evaluates organizations across five stages, ranging from reactive to visionary, based on culture, incident response, risk management, and leadership commitment to reliability. In industrial contexts, the EY EHS Maturity Model assesses environmental, health, and safety systems, often serving as a proxy for operational reliability. Many firms also adopt Safety Culture Maturity Models to benchmark cultural alignment with safety and reliability goals, often using levels like “pathological” through “generative.” In software and tech operations, Service Maturity Assessments help audit systems for reliability, observability, and recovery readiness – particularly in Site Reliability Engineering (SRE) contexts. Organizations in asset-intensive sectors may also use frameworks such as Reliability-Centered Maintenance (RCM) and Risk-Based Inspection maturity models to assess failure modes, inspection regimes, and operational resilience. These frameworks provide structured criteria to evaluate reliability practices across leadership, systems, human factors, and cultural behaviors, making them adaptable across a range of high consequence industries.

How do high reliability organizations address diversity and inclusion in safety culture?

By valuing diverse perspectives, creating inclusive dialogue, promoting psychological safety, and ensuring equitable recognition of expertise and voice.

What emerging technologies are enabling the next generation of HROs?

Technologies include AI for anomaly detection, IoT monitoring, automation, augmented reality, digital twins, collaborative dashboards, and explainable AI.

How can we reduce delays in maritime material procurement?

HRG aligns QA with throughput, tying procurement controls and supplier oversight to faster PO flow, fewer rework loops, and on-time, audit ready deliveries.

What’s the cost impact of poor quality in maritime or defense contracts?

Rework, delays, and compliance escapes all compound cost. HRG reduces cost of poor quality (CoPQ) by standardizing QA processes and driving measurable weekly performance improvements.

How do we ensure compliance without slowing down the supply chain?

We embed compliance into the flow from hardened receiving and calibration to traceable procurement and supplier monitoring, so quality assurance supports, not blocks, velocity.

How can I be confident our suppliers are audit ready?

HRG standardizes responsibility-based checklists, audit scripts, and QA routines that keep suppliers continuously prepared, not just reactive during audits.

What QA practices reduce CAR aging and escape rates?

We implement weekly metric driven QA routines (CAR aging, escape rate, closure days) and close the loop fast, cutting delays and keeping quality issues contained.

How do we reduce rework and improve first pass yield?

By reinforcing frontend QA in procurement, receiving, and documentation, HRG ensures material moves right the first time, reducing costly rework cycles.

What’s the ROI of hardening QA processes?

Fewer contract risks, faster delivery, and lower internal cost of quality, often with tangible performance gains within weeks, not months.

A High Reliability Organization is one that operates in environments where failures or errors can have severe consequences, yet retains very low rates of adverse events. It does so through deliberate leadership, a culture of safety and reliability (not just compliance), structured and formal processes, ongoing learning.